In flotation with dissolved air, combining small bubbles with each other and turning them into larger bubbles leads to a reduction of the effective surface of contact with very small suspended particles. Also, large bubbles have a greater shear force, which leads to the breaking of particles and their transformation into smaller particles.

In the usual methods, surfactant is used to produce small bubbles, which leads to pollution and additional costs. The smaller the size of the bubbles, the more contact with small suspended particles and the efficiency of flotation increases.

Nanobubbles can significantly increase the efficiency of the flotation process. Particles in water have a surface charge. Surface charge, like surface area, is an important parameter that directly affects the performance characteristics of any suspension, such as surface chemical activity. Surface charge effects can usually be neglected for large solids, but they are of great importance in the description of colloidal behavior. The negative surface charge of nanobubbles along with their high concentration causes a significant increase in the amount of collisions with suspended particles and as a result improves the flotation speed.

In flotation by conventional bubbles, the suspended particles stick to the outer surface of the bubbles and some suspended particles may be separated from the bubble on the way up. While nanobubbles surround the suspended particles and the probability of these particles being released is very low.

In flotation by conventional bubbles, the suspended particles stick to the outer surface of the bubbles and some suspended particles may be separated from the bubble on the way up. While nanobubbles surround the suspended particles and the probability of these particles being released is very low.

Most flotation processes, such as the separation of negatively charged colloidal materials, are highly dependent on coagulants and flocculants in order to maximize particle collision and clot production.

The high concentration of nanobubbles along with their strong surface charge increases the collision rate and also enhances the formation of clots, and therefore one of the significant effects of nanobubbles is reducing the amount of chemicals needed in the flotation process.

The nano bubble generator of Nano Bubble Energy Company can be a very effective supplement in the flotation process. This generator has the ability to produce billions of nanobubbles that stick to the suspended particles in the water and cause them to float.

applications

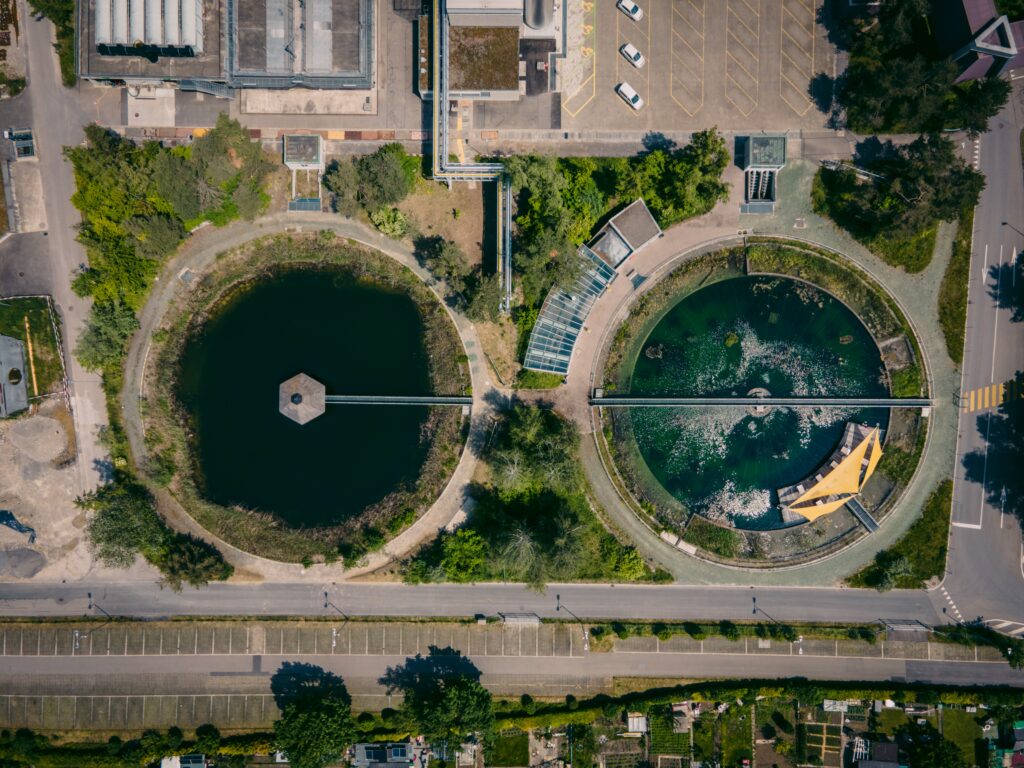

Dissolved air flotation (DAF)

Membrane Bioreactors (MBR)

Clarifier

Advantages

Improving the efficiency of flotation

Reduce process time

Increasing the efficiency of removing suspended solids (TSS)

Reduction of space due to the elimination of large dissolution tanks

Reducing the additional costs of urban sewage and chemical costs

Gas transmission with very high efficiency

Eliminate annoying plumbing connections

044 34228120

0914 165 4908

Mako commercial and industrial free zone

Wali Asr town, Mako Free Zone Organization Technology Center, Unit 5

Postal code: 5861994308

info@nanohobab.com

Hasti Color Collection as one of the most advannce manufacturing factories